About Sinfiny

Leading the Transformation

Since 2018, at Sinfiny Smart Technologies, we have led the transformation toward smart factories, offering innovative solutions to address the challenges of Industry 4.0.

Headquartered in Paterna, Valencia, our global focus on advanced engineering ranges from automated production lines and robotics integration to software programming and strategic consulting. Being part of the prestigious Bouwen Group reinforces our commitment to excellence, allowing us to collaborate with leading strategic partners and exceed international standards.

Over the years, we have evolved from the automotive sector to other key sectors such as technology, energy, and modular construction.

Our mission is clearly defined: “We innovate to transform ideas into solutions that positively impact society.” We have a multidisciplinary team that is the pillar of our success and the engine of our continued growth.

Services

We provide complete solutions for the projects we undertake

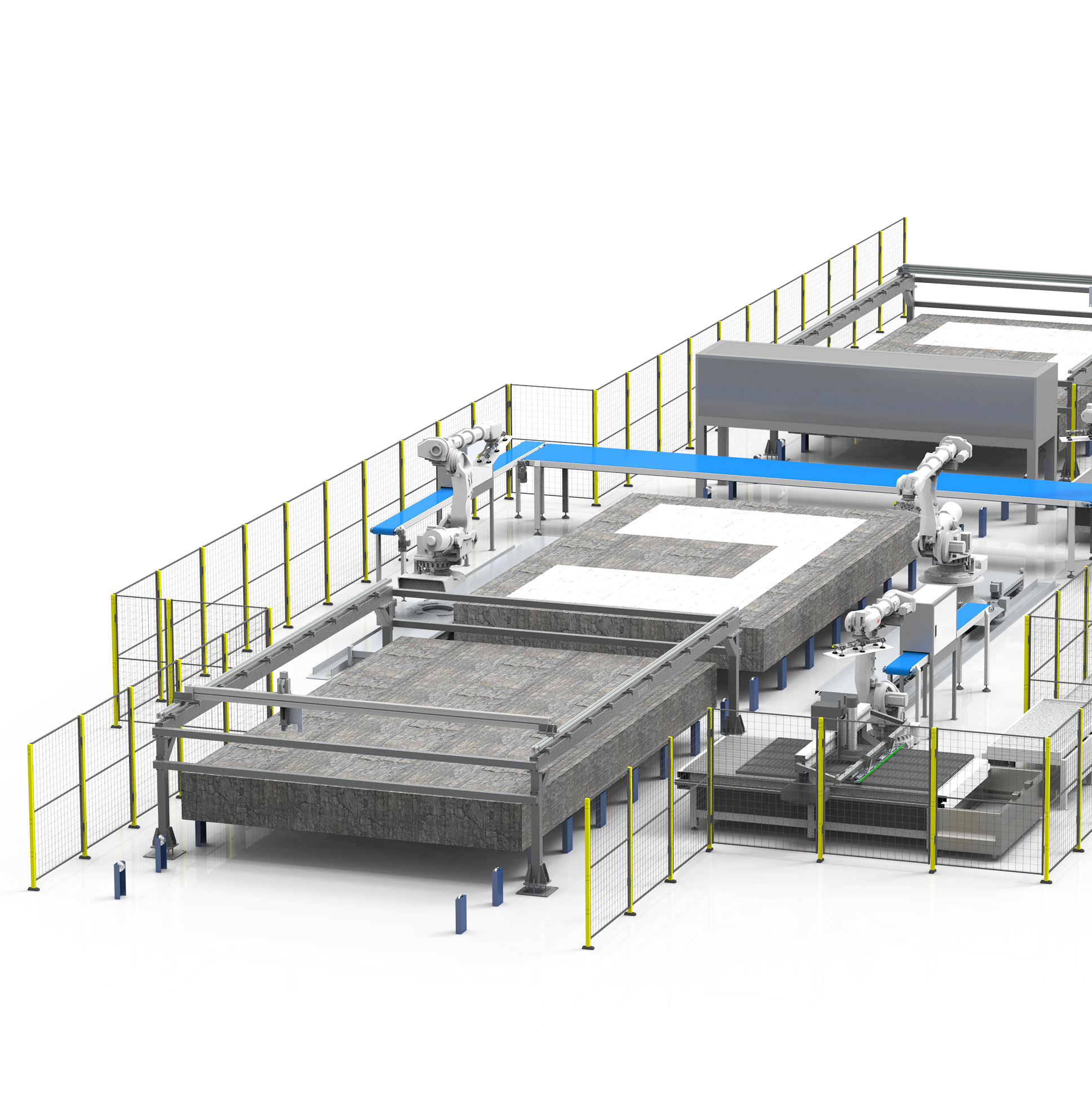

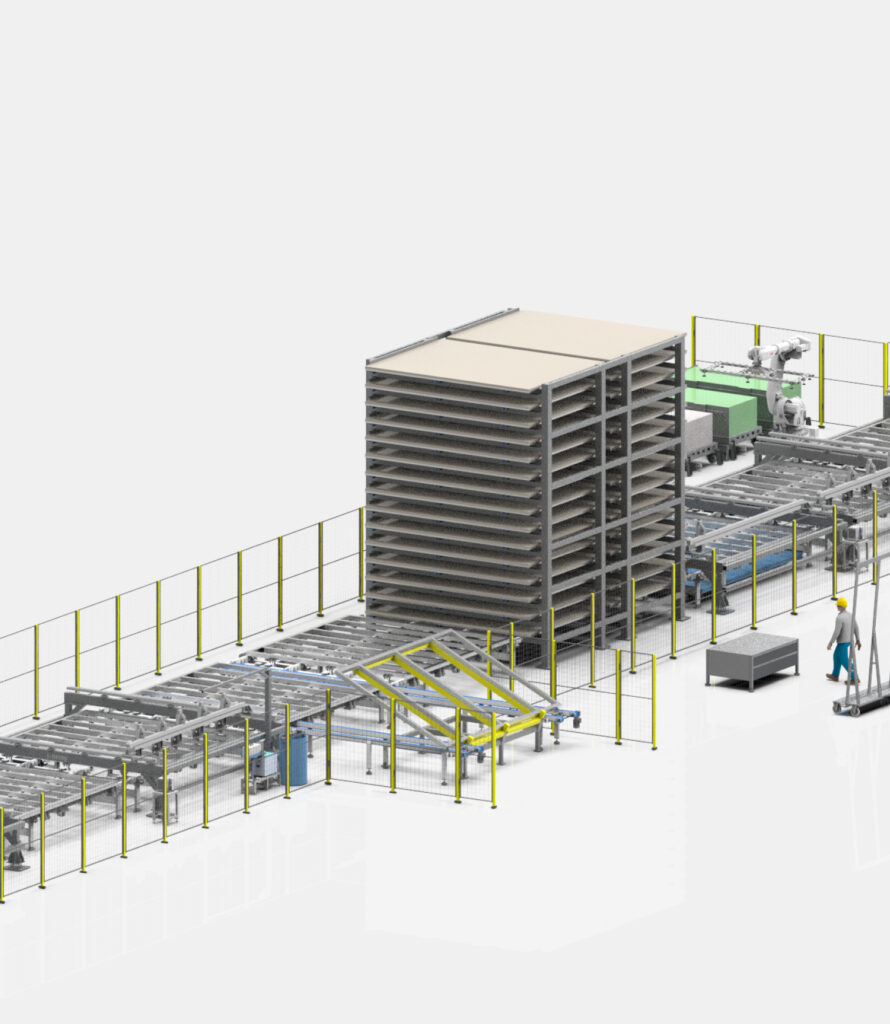

Our company specializes in turnkey projects, covering all the necessary phases to ensure the success of each project.

From a thorough process analysis, through customized production line design, to the integration of advanced technologies, we work to offer comprehensive solutions. We handle commissioning, ensuring everything runs optimally, and we offer maintenance services to guarantee continued performance over time.

With our comprehensive approach, we deliver results that inspire confidence and satisfaction.

Mechanical Engineering

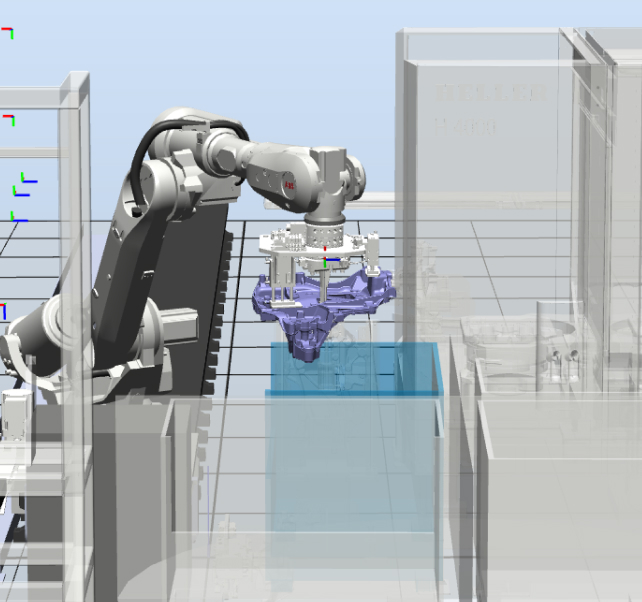

We use tools such as SolidWorks and AutoCAD to design, analyze, and optimize mechanical systems, improving industrial and technological processes.

Electrical Engineering

Process Consulting

Programming and Software

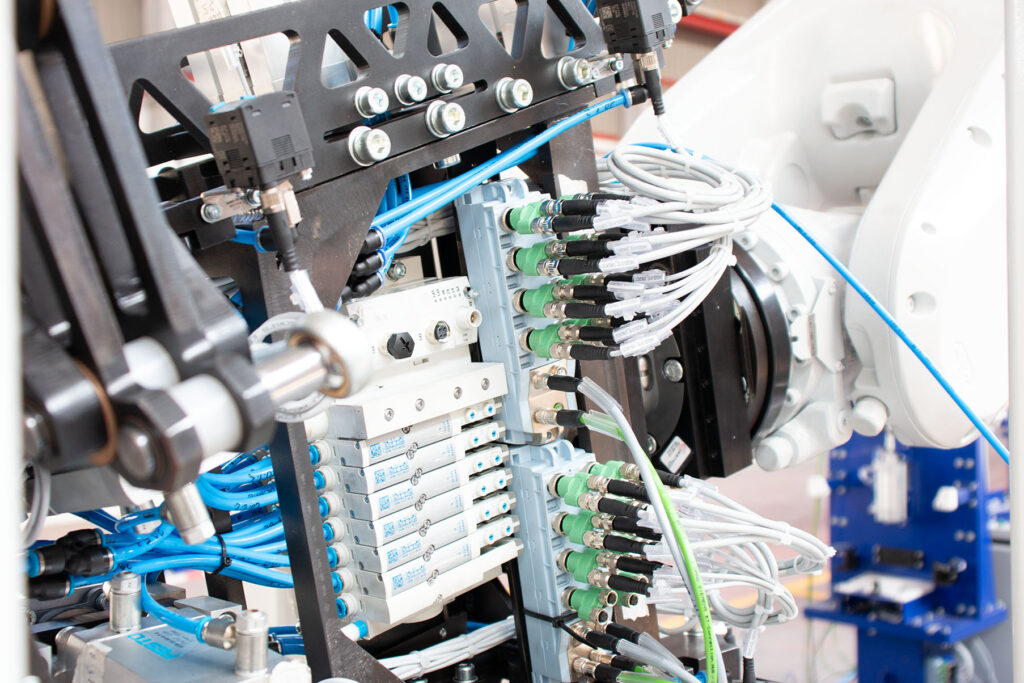

Optimization of production processes, reduction of cycle times, and advanced simulations. Implementation of machine vision, SCADA systems, and traceability. Integration of new equipment using advanced automation technologies and industrial robotics. Diagnostics and problem resolution with a focus on customized programming adaptable to specific environments. Development and programming of PLCs and robotic systems, and their integration with quality control and real-time monitoring systems. Implementation of efficient motion algorithms and communication systems between robots and peripheral equipment.

Technical Support Service

Sectors

We want to be the engine of success for our clients

Our experience in different sectors brings a global vision to any project.